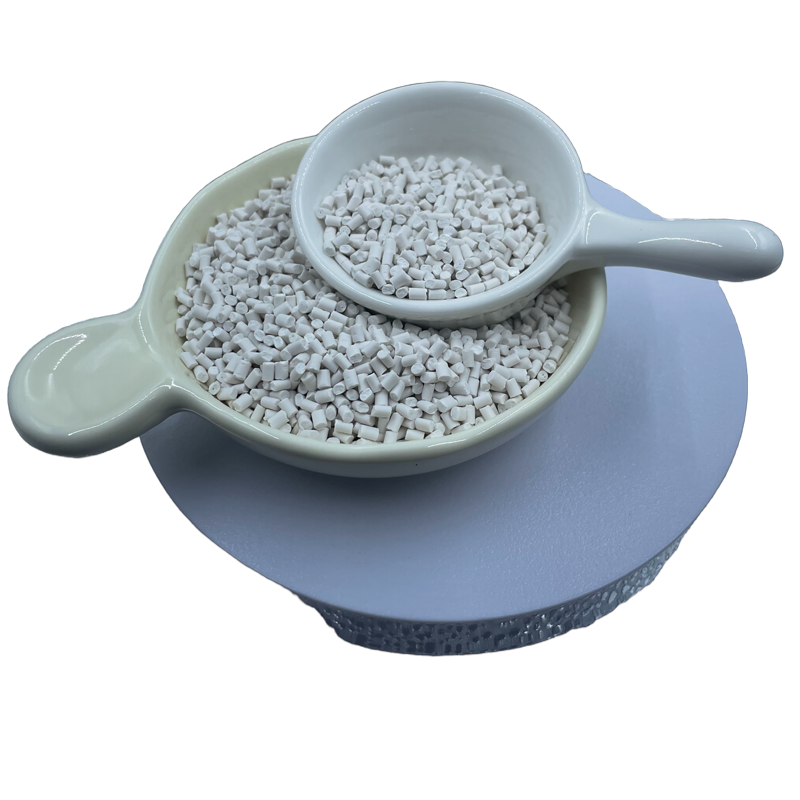

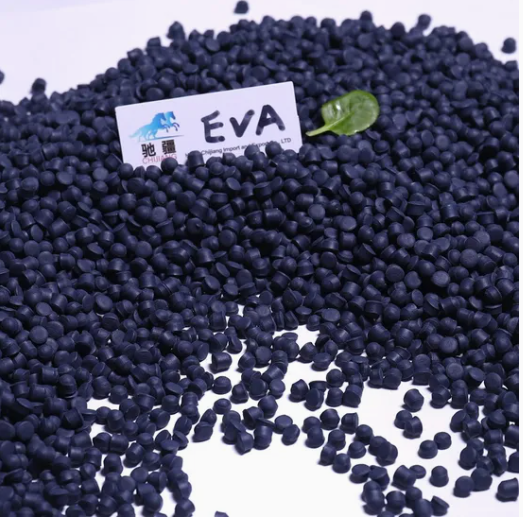

High-Performance Flame Retardant ABS Granules for Injection Molding

High-Performance Flame Retardant ABS Granules for Injection Molding

Excellent mechanical properties**

- High impact resistance (butadiene contributes toughness)

- Good rigidity and strength (styrene contributes hardness)

- Wear resistance, suitable for manufacturing gears, housings, etc.

2. **Good processing performance**

- Easy to injection mold, extrude, 3D print (such as ABS materials commonly used in FDM printing)

- Can be electroplated, sprayed, and bonded, suitable for surface decoration

3. **Chemical resistance and thermal stability**

- Acid, alkali, and grease resistant (but soluble in ketones and ester solvents)

- Operating temperature range: -20°C ~ 80°C (some heat-resistant grades can reach above 100°C)

4. **Electrical insulation**

- Suitable for electronic and electrical housings, sockets, switches, etc.

5. **Low cost**

- Compared with engineering plastics such as PC (polycarbonate) and PA (nylon), ABS is more economical